WvSC MRO–DI 1

Digitization of diagnostic imaging - Werner von Siemens Center for Industry and Science (WvSC)

PROJECT DESCRIPTION

Maintenance,Repair and Overhaul (MRO)

OBJECTIVES

The objective of the MRO project is to develop new technologies for repairs including upgrades for high-efficiency gas turbines. Some components in gas turbines, e.g. the turbine blades, are subject to constant wear due to corrosion and oxidation. They are regularly removed, repaired and then operated again with the same running times or - after certain intervals - replaced altogether.

The use of future technologies such as digital solutions or additive manufacturing processes can result in product and process innovations that enable operating intervals to be extended. In addition, improved properties can contribute to greater efficiency and lower emissions.

WORK PACKAGE

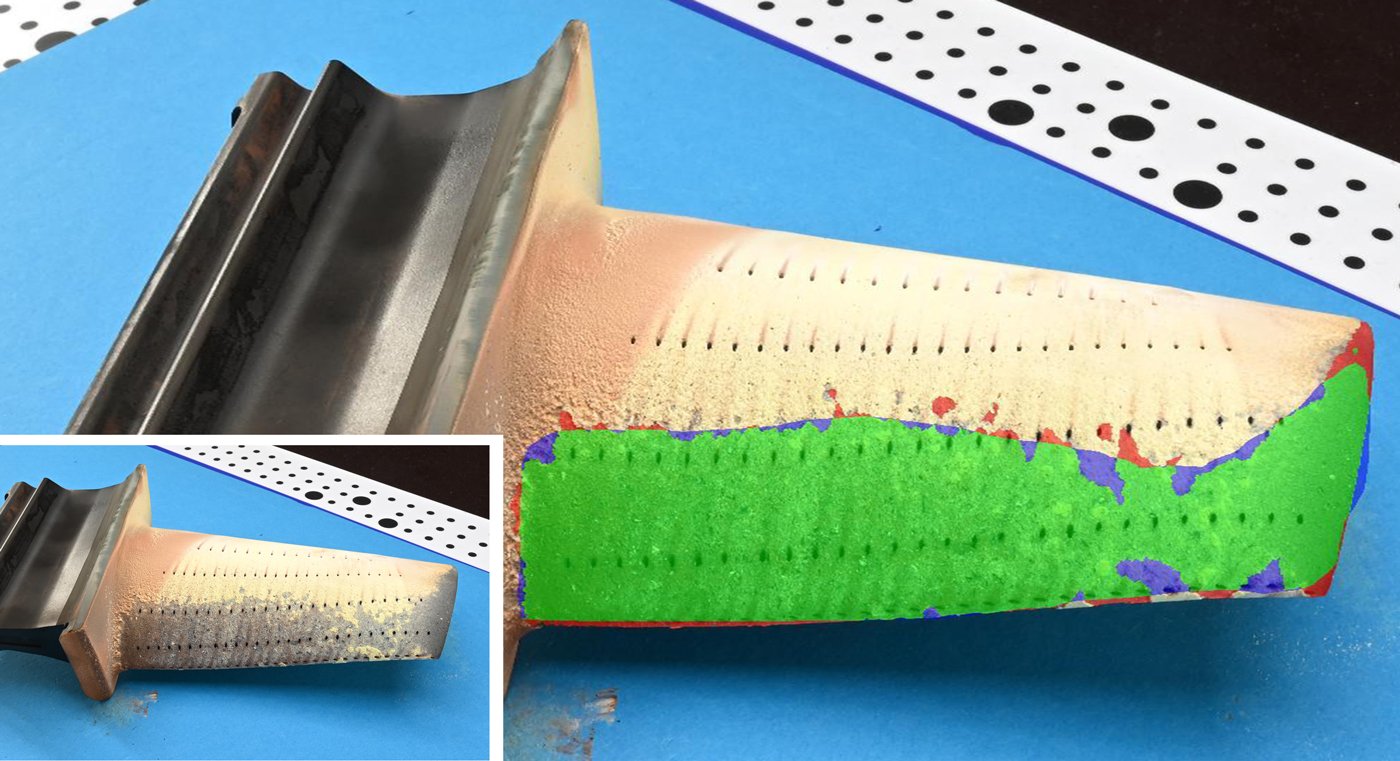

In the work focus of digitization of diagnostic imaging, appropriate methods are to be investigated with which turbine blades can be both digitized and classified in terms of defect types and dimensions. Both 2D and 3D measurement methods will be considered. With the 3D measurement methods, the blades are to be transferred into a suitable CAD format, with which deviations of the nominal shape from the actual shape can be determined. High-resolution 2D sensor technology will be used to investigate the extent to which the surface of the blades can be inspected and checked for defects. The 2D images are to be converted to the 3D shape in order to obtain a digital model of the current condition of the blade with localized and classified defects. This model, which is as detailed as possible, can then be made available and documented via the Digital Twin for subsequent work steps along the MRO process chain.

OUR CONTRIBUTION

In the work package, Gestalt Robotics takes over the derivation of requirements for the defect catalog and supports its creation with expertise from an implementation perspective. This is followed by the conception of the software architecture and interfaces with the selection of a trade-off for the incoming goods inspection. This is followed by the implementation of the software architecture, as well as a test and verification logic. Based on this, various methods for image recognition based on neural networks are implemented and accompanied by unit and integration tests. Furthermore, the definition of metrics and the determination of quality characteristics will be done in this context. Finally, final tests, bug fixes, optimization and implementation of improvement suggestions are performed.

Key facts

Digitizing System

(Partially) automated 2D/3D data acquisition

Software and hardware integration

Modular software architecture

2D Image Processing

Defect detection on surfaces

Use of machine learning methods

Interactive Active Learning

3D Feedback

Traceability of CAD models

Generation of the volume defect model

2D-3D projection of defects

AI Life Cycle

Holistic lifecycle management

Integrated quality assurance

Automatic deployment and updates

PartnerS & CONSORTIUM

Siemens Energy AG

Selection and provision of the database from data history, preparation for implementation of the digitization system in production, provision of labeled images, evaluation of the software solution with regard to the necessary interfaces, analysis of usability in the digital twin, evaluation of the results

Fraunhofer IPK

Creation of a defect catalog, design of image processing hardware, mechanical design of a digitizing function pattern, feasibility studies, selection of a suitable image processing methodology and description of interfaces, iterative optimization of defect detection and classification, position and orientation determination of the camera with respect to 3D scan data, characterization of damage cases according to type and area of damage occurrence

Funding

Berlin Senate, co-financed by the European Regional Development Fund (ERDF)

Program

“ProFIT – Projektfinanzierung”

Duration

01.2020 – 12.2022

Project Management Agency

Investitionsbank Berlin (IBB)

ProjeCt poster

Project poster (German) as printable PDF

This project is/was financed with funding provided by the Berlin Senate, co-financed by the European Regional Development Fund (ERDF) under the “ProFIT – Projektfinanzierung” program and managed by the Project Management Agency Investitionsbank Berlin (IBB). The author is responsible for the content of this publication.